Vortex Cooling: A Very Useful Tool In Controlling Heat Stress

- By Ross Di Corleto

- 20/04/2022

- No Comments

The vortex tube is a useful addition to the heat stress control toolbox.

Also known as a climate control tube as it is sometimes referred to or the Ranque-Hisch vortex tube (which it is rarely referred to) it is a very useful and cost-effective cooling device. However, the principle of operation is not quite as complicated as it would seem.

How it works

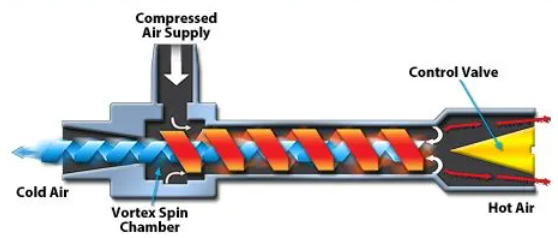

Using an ordinary supply of compressed air as its source, vortex tubes create two streams of air, one hot and one cold.This is done by introducing compressed air at an angle into the body of the vortex tube which is designed to spin the incoming air at extremely high velocity (up to 1,000,000 RPM).

This air is split into two streams, one hot and one cold. The hot stream forms an outer vortex with some being ejected out the bottom past the control valve. The cooler stream is re-directed up the centre of the tube and exits via an outlet at the top.

Therefore the tube itself has no actual moving parts apart from a control valve at the bottom, which adds to its reliability. The temperature may be adjusted over a wide range by varying the compressed airflow using the control valve on the hot end exhaust.

As an approximation, various types of Vortex tubes can produce:

- temperatures from -46° to +127°C (-50° to +260°F)

- Flow rates from 1 to 150 SCFM (28 to 4248 SLPM)

It can be used to introduce cooled air into cooling vests, air fed respirators such as those used in sand blasting and welding helmets. It allows the wearer to adjust the incoming air to their preferred temperature. Available in a number of different shapes and sizes, is quite small and readily obtainable from several PPE suppliers.

They have been used successfully in a number of hot work scenarios. The vortex tube is particularly suited to welding work in hot environments where fans are not an option due to potential disturbance of the gas shielding process.

Its one drawback is that it requires a supply of compressed air usually via an airline.

Bottom Line

The vortex tube cooling system is a very useful approach for a number of specialist tasks in hot environments. If the requirement of a compressed airline is not an issue for the task, then vortex tubes and associated PPE should be considered for hot thermal environments.

Copyright © 2024

Copyright © 2024

Leave a Reply